As a pharmacy owner, you are used to dealing with refrigerated products such as medications and vaccines. In many pharmacies you will often see small household refrigerators in place of larger, industrial fridges. Although having small refrigerators is appealing due to their low cost, they are subject to intermittent or potential operating inconveniences, including but not limited to:

- A faulty defrost cycle

- Insufficient cooling outflow

- Excess ice buildup or frost in the evaporator

- Refrigerant compressor with low or medium durability

- Inconsistent temperature control

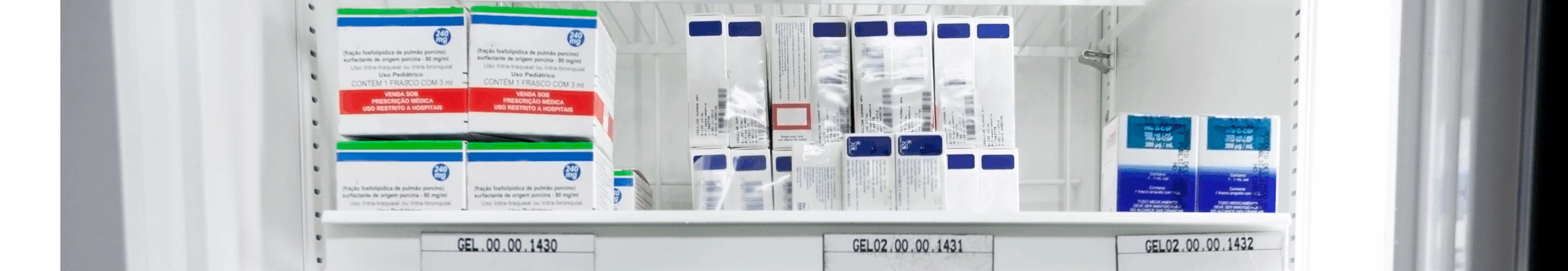

These low-cost refrigerators are not comparable, in terms of quality and durability, to the kind of refrigerators used in hospitals, labs, and medical or commercial businesses. Purpose-built refrigerators, with higher purchase costs, come with very strong technical reliability. They are designed for professional use and are typically equipped with a temperature alarm that can connect to the central alarm station overseeing your premises, which is highly recommended.

Pharmacies have a large inventory of perishable pharmaceutical products, and therefore, a loss resulting from a lack of refrigeration can have a major financial impact on your business.

Best practices for refrigerators and refrigerated products

To prevent the risk of serious financial loss, a high-quality refrigerator designed for professional use is an essential investment. If you already have a high-quality fridge, make sure you have an integrated temperature alarm that allows you to act quickly in the event you need to transfer your perishable products.

In order to keep your pharmacy and its products safe, we’ve compiled a list of some additional tips for your refrigerators below:

- Be careful not to overload the refrigerator with products that may obstruct airflow and the cold diffuser. This causes insufficient cold distribution and may result in a refrigerator malfunction, as well as the loss of perishable products.

- If the fridge is not level and/or the door is misaligned or not adjusted properly, you will not have the best seal, and cooling will be a problem. The door gasket must be flexible and in good condition. Take the time to properly close the door for an airtight seal.

- Prepare for potential refrigerator breakdowns or malfunctions by creating an emergency plan that indicates where to quickly transfer perishable products for storage, especially if repairs will take a long time.

- Allow for open space of air flow at the back of the unit (as recommended by the manufacturer) to ensure optimum performance of the condenser.

- Consider locating a dry ice (carbon dioxide or CO2 in the solid form available as blocks or pellets) supplier in your area. This will allow you to temporarily store your refrigerated products on location and carry on with business operations.

- Protect yourself with a preventative maintenance contract from a recognized refrigeration company. If you have such a contract for other equipment (air conditioning), adding your refrigerator to it should be an easy process.

- Make sure that all of your refrigerators are equipped with temperature alarms that are connected to your central alarm station.

- Contact the company you purchased your refrigerator(s) from, as refrigeration companies can recommend temperature alarm models that easily hook up to your existing panel and central alarm station.

How insurance protects your refrigerated medications

Although preventative maintenance is extremely important for your pharmacy, so is having an adequate insurance policy.

Your insurance program should provide you with coverage for losses related to refrigerated medications, which may give you some peace of mind. However, you should know that a loss affecting perishable products (indirect loss) must have an “accidental” cause to be covered, resulting in equipment breakdown. Failure or damage due to erratic refrigerator performance, or even a simple power outage, may not constitute an indemnifiable breakdown under the contract.

If the unit’s failure is not technically considered an “accidental” breakdown, the unit repair and monetary loss from product damage will not be indemnified by the insurer. In the event of a breakdown, the adjuster or a technical representative from the insurer will determine the source or true nature of the loss.

Here are some admissible (indemnifiable) causes that should be covered in your policy:

- Electrical arcing in the motor

- Fractured internal parts in a compressor

- Physical breakdown of any other component

These causes are generally considered to be excluded (non-indemnifiable) from your policy:

- Corrosion of the fridge or one of its components

- General wear and tear or deterioration of the fridge or one of its components

- Failure or erratic performance of a control

Take care of your business, your workers, and your bottom line

Although implementing the tips above can help reduce the risk of loss, having the proper insurance policy is truly the only way you are protected. That’s when business insurance can be helpful. To learn more about how a tailored policy can help protect you, your employees, and your bottom line, visit our consumer and business services insurance page today!