Fires aren’t always caused by open flames. In many cases, poorly maintained electrical panels, wiring, and under-rated circuit breakers or fuses can be to blame. Do you suspect that your machinery and equipment might be overused, improperly used, or poorly maintained? A thermal image scan can help detect these problems.

What is thermal imaging?

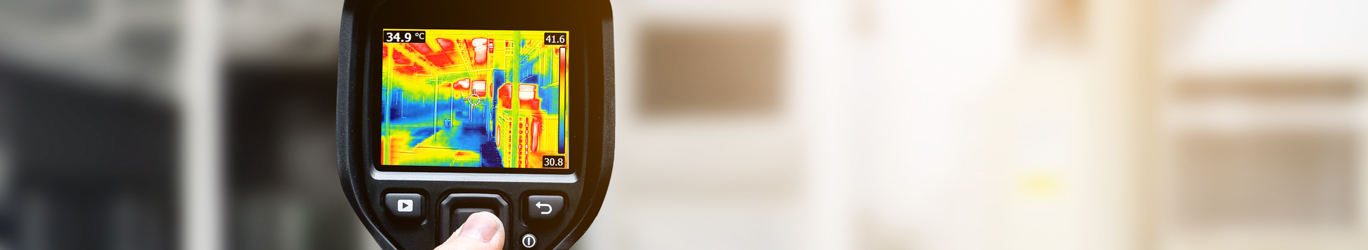

Thermal imaging – or thermography – is the process of using a specialized camera to measure infrared radiation emitted by a given surface. It converts that data into a two-dimensional image with a unique colour gradient that relates to fluctuations in temperature.

All facilities are subject to thermal loss, moisture intrusion, and equipment failures. Manual inspections can get to the root of the problem, but they can be time consuming and destructive – think about what it can take to go through a wall or complex piece of equipment to get to the suspected issue. Thermal imaging helps you uncover problems more efficiently and safely, given that it’s non-invasive and visually concise.

Thermography is used for a variety of purposes, and can provide many benefits:

- It can quickly locate problem areas and potential water-related issues

- It eliminates the need for exploratory demolition

- It can minimize long-term repair costs

- It helps control claims costs

Find your hot spots, protect your operations

Conducting thermal scans on electrical or mechanical equipment can reduce the likelihood of problems long before they arise. Although it is non-invasive, thermal imaging is used when electrical systems are in service, preferably under peak loading and with many components exposed. If transformers, switchgears, motor starters, and control panels begin to fail, they may generate heat through infrared radiation – this evidence is what the camera can detect.

Thermal imaging can also be a valuable part of your business continuity plan. While it can help minimize damage and reduce potential issues, what you may not realize is how routine thermal imaging can also reduce the likelihood of downtime, loss of production, or even loss of your entire facility.

How and where can thermography be used?

Once a consultant identifies the need for an infrared assessment (usually during a risk assessment or at the request of your insurance professional), they’ll determine the type of thermal scan your building or equipment requires. Here are a few of the ways thermal imaging can be incorporated into your loss prevention program.

Preventing roof failures

Did you know that most roof failures occur within the first seven years? Even if your roof is relatively new, consider a thermal scan to reveal accumulated moisture below the surface. For example, mould is a growing concern in areas with potential moisture accumulation. Infrared inspections can detect issues on roof membranes, saving you the effort and expense of dismantling and replacing the entire surface.

Water has a high thermal capacity, which means it will typically release heat at a slower rate than other roof materials, and that difference in temperature can be detected with a thermal scan. But this means that the temperature of the roof and surrounding material will make a difference, so assessments of roof surfaces are best done in the evening hours, after the thermal energy that the roof accumulated over the course of the day has dissipated.

Detecting electrical hot spots

The National Fire Protection Association (NFPA) estimates that 20% of manufacturing fires are related to electrical system failures. Given that exposed electrical failures could also lead to serious injury or death from electrocution, electrical risk is not something to be taken lightly.

Thermography for electrical systems can accurately detect hot spots generated from issues like:

- Loose electrical connections

- Unbalanced loads

- Overloading of electrical circuits

- Deteriorated electrical insulation

- Damage caused by vermin chewing on wires

Problems like these can lead to increased maintenance costs, equipment damage or failure, service interruptions, and fire hazards. Fortunately, the resistance or overload that stems from a deficient connection between components will show up in a thermal image – the temperature will appear elevated compared to similar load conditions of similar connection types. The thermal scan can also determine variances in oil levels within transformers.

Spotting issues with equipment and machinery

Thermal imaging can also be used on mechanical equipment to detect issues like motor bearing problems or motor shaft misalignment. When operating under normal load conditions, thermal imaging scans on equipment and machinery can detect:

- Excessive friction

- Non-uniform heat flow

- Temperature distributions

- Motor and bearing wear

- Pipe insulation

- Tank levels

Spotting issues early on gives you the opportunity to take corrective action, which helps reduce the chance of a major, costly breakdown and business interruption. While thermal scans can have the greatest impact in larger buildings and older structures containing older electrical components, exposed wiring, high-value or critical production machinery, and boilers, both small and large businesses can benefit from using this technology.

How risk management professionals can help

Thermal imaging involves advanced technology, and it makes sense to work with an expert for efficiency, safety, and accuracy. But capturing a thermal image is just the first step. Next, you’ll need to have someone capable of interpreting the information in the thermograph distill and communicate the findings – that’s where a risk management professional comes in.

Our Risk Services professionals are trained in executing thermal assessments and presenting the results. They can help explain the image and create actionable steps to mitigate those hidden risks in your workplace. The team will generate a comprehensive infrared report, and then you can reach out to your electrician with pictures of the equipment that requires the repair to get the work underway.

Thermal imaging is one example of how a specialized risk management approach can help protect your bottom line. Have you given attention to other best practices to safeguard your workplace and the people within? Our experts have some more expert guidance on building site safety that can go hand-in-hand with technological tools like thermal imaging.

Learn more about how our team can work with you to build a risk management plan and help protect your business on our Risk Services page.